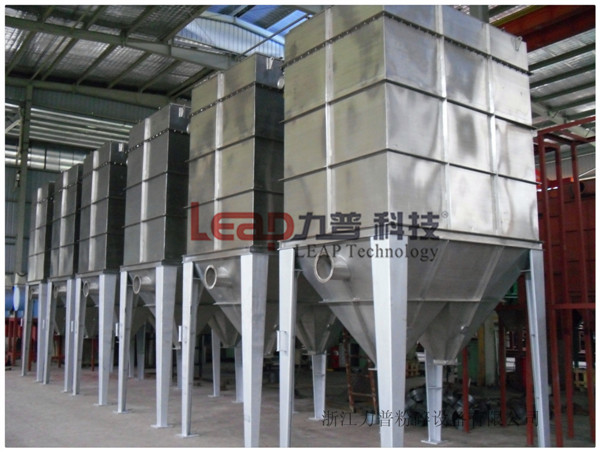

DMC series square pulse dust collector

Application field

1)Suitable for collecting a mass of floating dust in large area.

2)Apply to the big central dust collection system which has multistage, such as welding, grinding, polishing, cutting, drilling and so on.

3)Apply to the work condition which needs to recycling large amount of dust or particles, such as cutting, packing, grinding, spraying, powering, organic glass processing, car manufacturing, etc.

Specialty

1.Compact structure

It's floor space is much smaller than those bag filter vacuum cleaner by collecting the same quantity dust. What's more,This series equipment has much higher filtering efficiency, smaller running resistance, easier to be installed and moved. It's the best choice in large dust cleaning systems.

2.Easy to use and maintain.

The board door of cartridge using handle control switch which can ensure the tightness and also be convenient to open the door to see the cartridge usage.

It can be equipped with a negative pressure meter to monitor the operation situation of the machine.

Use large capacity container with caster, and have a fixed method of opening & closing the dust collector to make sure the airtightness and easy to cleaning.

3.High efficiency & reliable

Add a spoiler in the inlet to clean the dust in advance,and no need to equip the front cyclone device or spark trap. So it can reduce the cost generated by operating. And also reduce the speed of wind and improve the filtering efficiency.

| Parameter¡¢Model | DMC-32 | DMC-48 | DMC-64 | DMC-80 | DMC-96 | DMC-112 | ||||||||||

| Filtration Area£¨Square meter£© | 24 | 36 | 48 | 60 | 72 | 84 | ||||||||||

| Filter wind speed£¨m/min) | 1.04¡«1.67 | 1.15¡«1.62 | 1.21¡«1.74 | 1.25¡«1.67 | 1.27¡«1.62 | 1.28¡«1.68 | ||||||||||

| Airflow£¨cubic meter/h) | 1500¡«2400 | 2500¡«3500 | 3500¡«5000 | 4500¡«6000 | 5500¡«7000 | 6500¡«8500 | ||||||||||

| Filter bags£¨pcs£© | 32 | 48 | 64 | 80 | 96 | 112 | ||||||||||

| Air consumption£¨cubic meter/min) | 0.032 | 0.048 | 0.064 | 0.08 | 0.096 | 0.11 | ||||||||||

| Inlet concentration£¨g/Cubic meter n) | 200 | |||||||||||||||

| Exit concentration£¨mg/cubic meter n) | 50 | |||||||||||||||

| Injection pressure£¨MPa) | 0.5¡«0.7 | |||||||||||||||

| Negative pressure | 5000 | |||||||||||||||

| £¨Pa) | ||||||||||||||||

| Equipment resistance£¨Pa) | ¡Ü1200 | |||||||||||||||

| Pulse valve | Specification | 1" | ||||||||||||||

| Quantity£¨pcs£© | 4 | 6 | 8 | 10 | 12 | 14 | ||||||||||

| Motor model and power | Y90S-2 | Y90L-2 | Y100L-2 | Y132S1-2 | Y132S1-2 | Y132S2-2 | ||||||||||

| £¨KW) | 1.5 | 2.2 | 3 | 5.5 | 5.5 | 7.5 | ||||||||||

| Net Weight | 1220KGS | 1470KGS | 1670KGS | 2150KGS | 2540KGS | 2880KGS | ||||||||||